The specimen

Usually, I am the guy in my peer group that is getting asked if I have any interest on insert broken device here. And usually, I will reject the offer as the input pile of faulty devices is already to big.

But with this device, it was different - I was allowed to keep it and it was also useful for me. It was an old Wahoo ELEMNT bike computer and it was free(if I can fix it). As man in my 30s it is anticipated demanded by society to get into cycling, it could fill the gap of missing gamification to keep my motivation on the bike high.

The malady

First of all, I want to point out that Wahoo is supporting the WFCC1 since 2016 with constant firmware updates at least until writing of this post, so I wont blame them for planned obsolescence. But, unfortunately, the USB port is sadly the weak part of the whole device. It lies behind a silicon cover flap on the back. Years of intense use of the previous owner showed that this material was not able to withstand the constant opening and closing - it was only a shadow of it's former self: a piece of silicone was left in one corner of the indent. In consequence, the USB port was exposed to the elements.

This might have caused things! Charging was nearly impossible unless you forced the charger cable to a very specific angle of the port (have fun doing this for the next two hours until the device is charged...). But maybe most disappointing was the port itself: A dated Micro-USB B receptical, and I got rid of almost all Micro-USB cables already some time earlier! But we can fix that(foreshadowing).

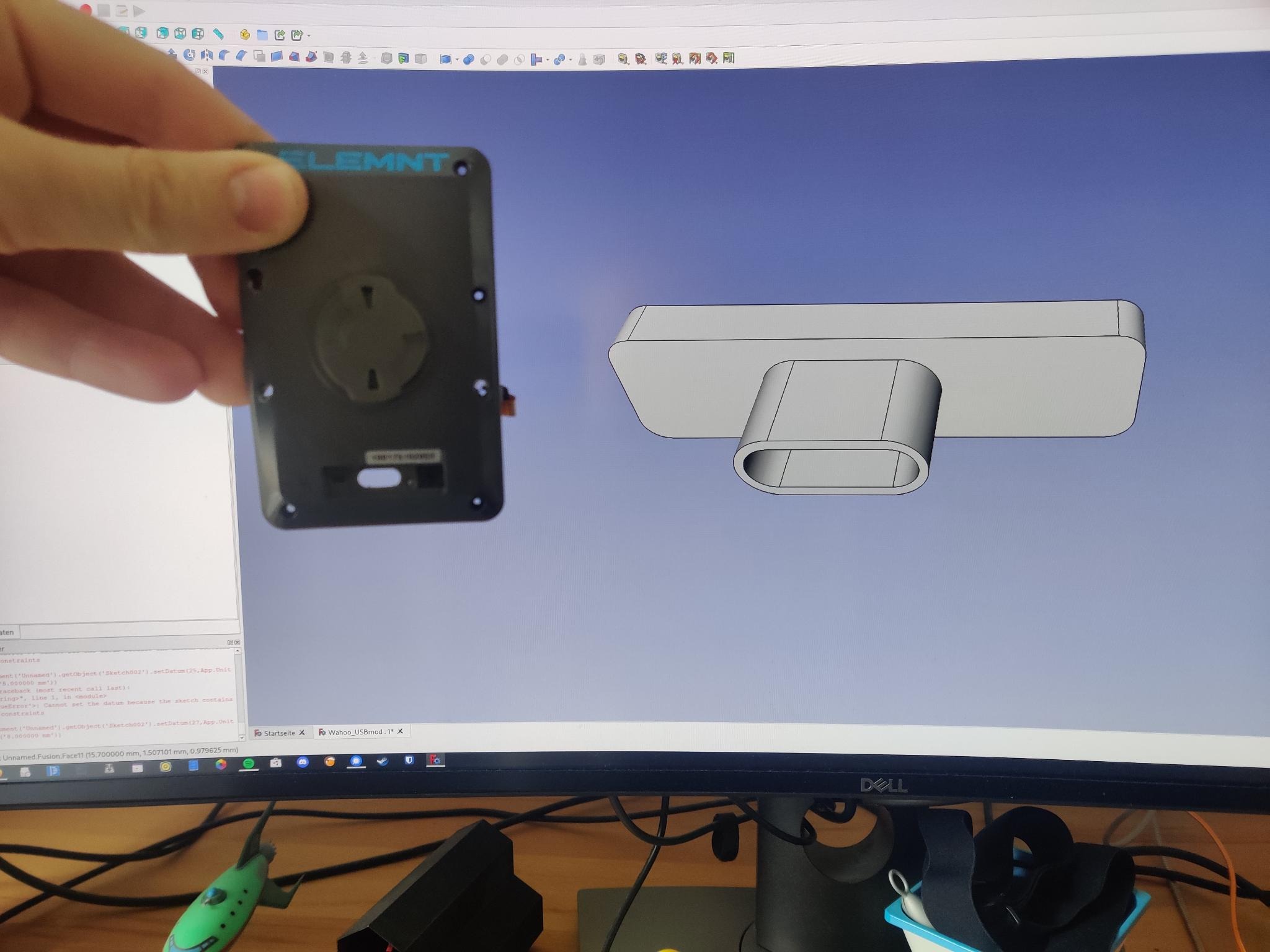

Designing a cure

I am an electrical engineer by trade, so the only CAD software I used in my life ist KiCAD and EAGLE. Parametric CAD was not totally new to me(I heard of it and the concepts) - but FreeCAD was. After grabbing my calipers and countless very old low-res YouTube tutorials I managed to design a negative of the backside indent to fit my new USB-C plug. Surprising to myself, the dimensions were right on the first iteration.

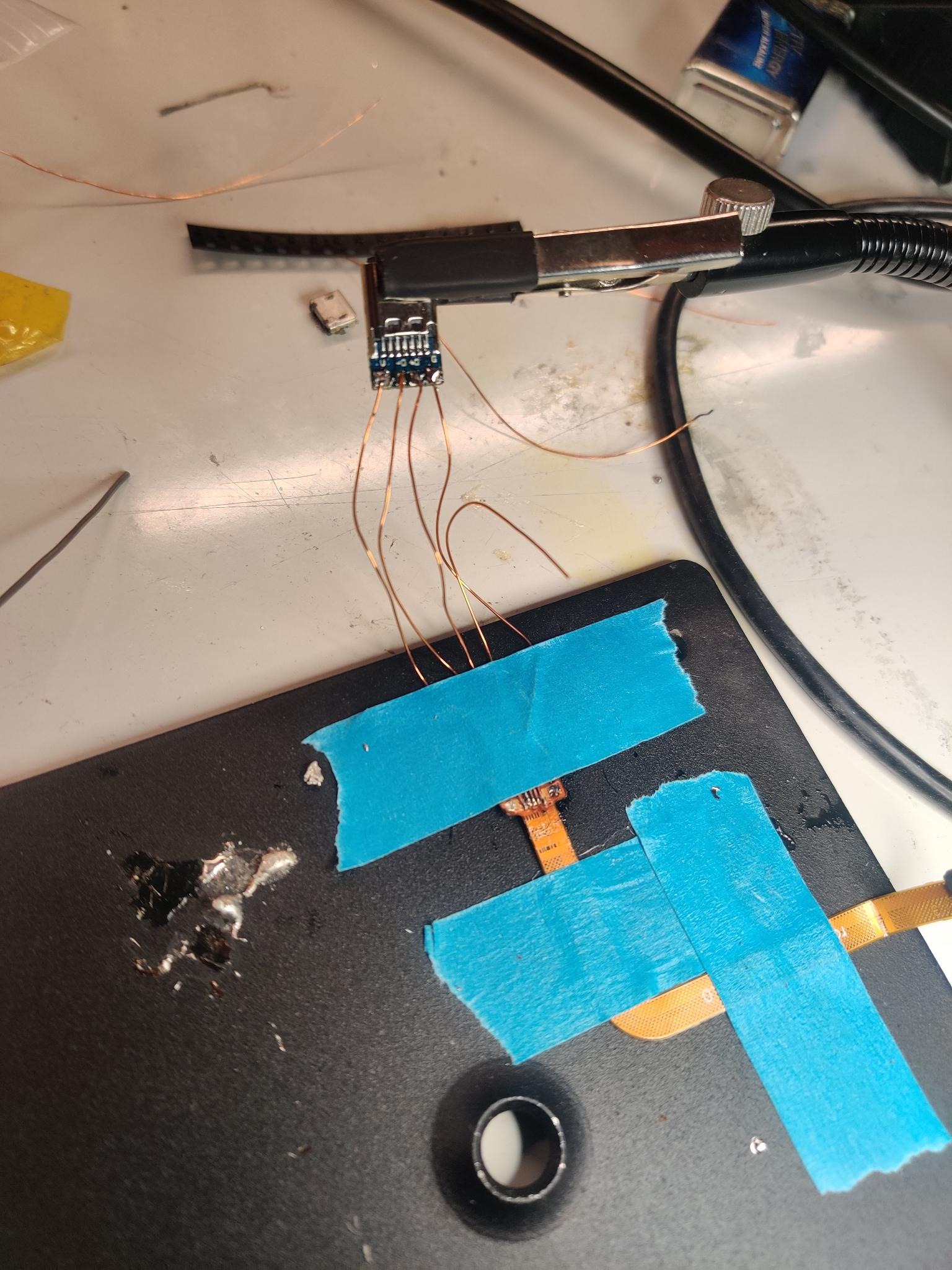

The Surgery

Soldering flat flex cables shouldn't really be done, but i didn't really have a choice, as the alternative was to de-solder the connector on the main PCB and use the tiny pads which are not really made for the mechanical stress that such copper wires can have cause. I didn't want to risk ripping a solder pad, as this would make the device very hard to repair (I count more than four layers, who knows where all the traces run to?).

I used the existing pads that were under the debris of the old connector after removing it. Fortunately, they were all intact and had a low resistance to the PCB connector. I had to use a lot of flux and multiple attempts to get the enamelled copper wire without shorts properly soldered, but it worked in the end.

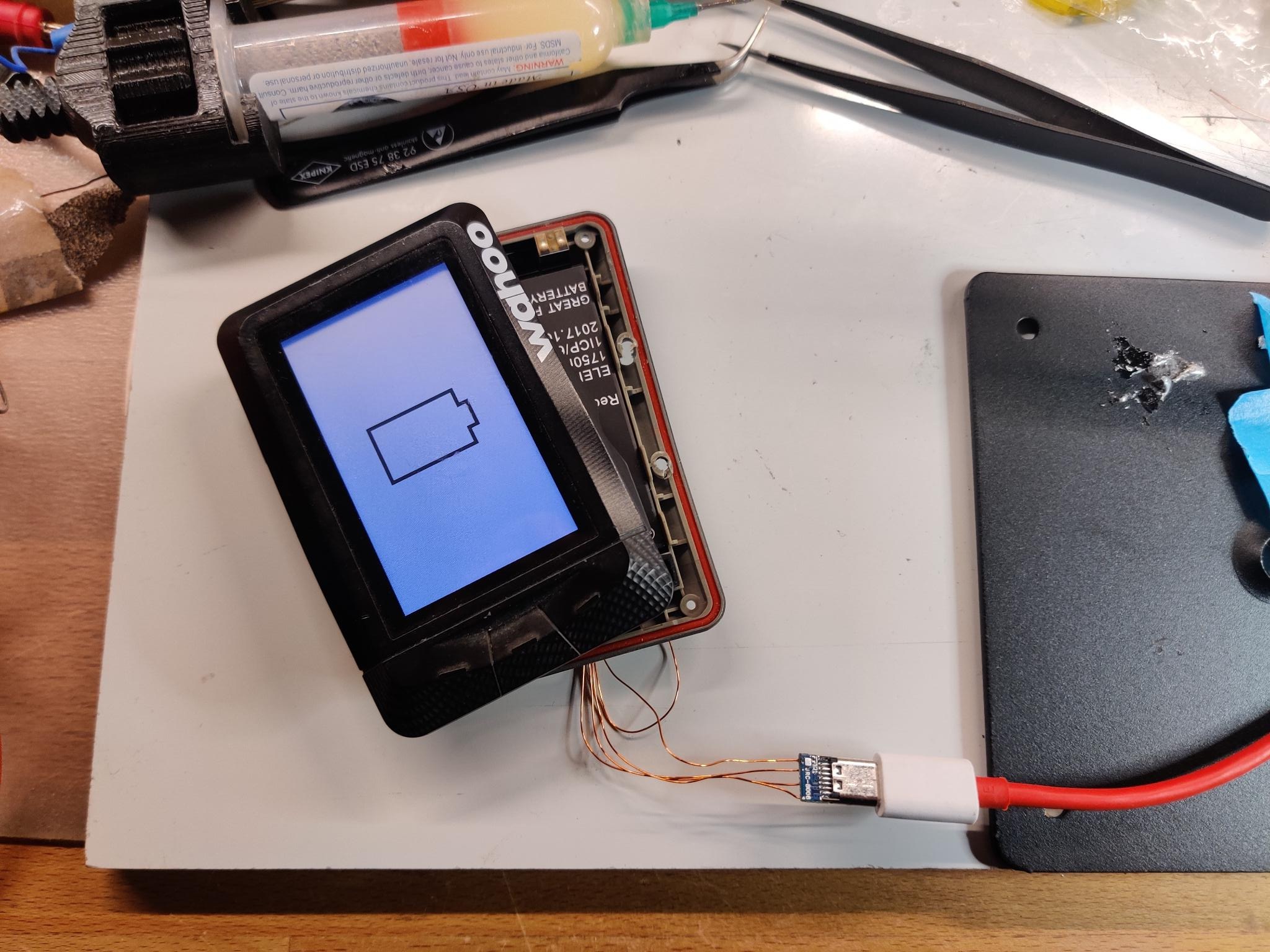

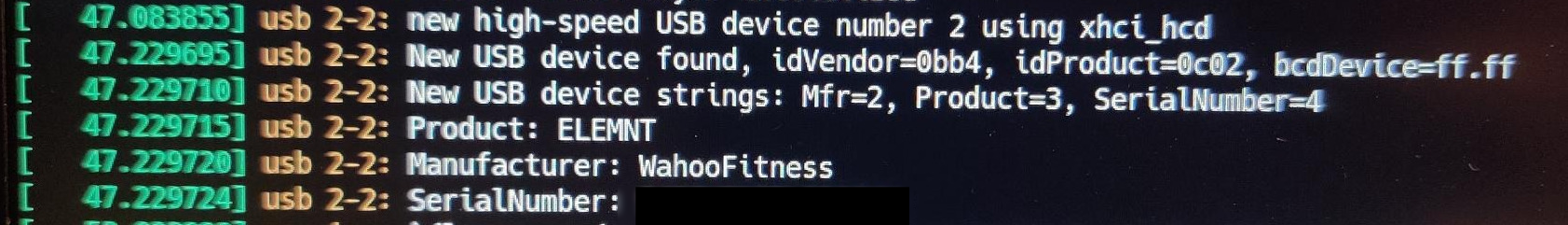

Soldering the USB-C brake-out board was pretty easy, hey, it was made for hand soldering, right? To stop any water ingress, the USB port was pressed into the 3D-printed port adapter and filled up with 2C-Epoxy. This will hopefully keep all the water out (And after almost two years, I can say: It did).  Before assembly, the ELEMNT was tested if it charges - success, what a relief. It even enumerated on my laptop, so the data lines were also intact (and didn't complain about the added wire length in the process - carefully length matched by hand, of course 😇!)

Before assembly, the ELEMNT was tested if it charges - success, what a relief. It even enumerated on my laptop, so the data lines were also intact (and didn't complain about the added wire length in the process - carefully length matched by hand, of course 😇!)

Healed?

Yes and no. I repaired the Wahoo ELEMNT in November 2023 and used it since then - but there were other issues. The tactile SMD switches behind the front rubber stopped working, and I had to replace them. But this is a story of another post.

I hope this post will save other bike computers from being scrapped - as I said, the software support ist still there. Or it encourages you to fix your broken device and tell others about it, reducing the E-Waste one device at a time.